|

|

Anything

has burrs deserves a try Anything

has burrs deserves a try |

Developed for precision

micro parts

Name Name |

Twirling motion precision finishing

machine |

| |

|

| Model |

HM-07R(IE3) 1.7L×4(container) |

| |

HM-07T(IE3) 1.7L×4(container) |

| |

HM-11R(IE3) 2.5L×4(container) |

| |

HM-11T(IE3) 2.5L×4(container) |

| |

|

Applications

|

|

|

|

|

|

Specifications

|

|

Model

|

HM-07R(IE3)

|

HM-07T(IE3)

|

HM-11R(IE3)

|

HM-11T(IE3)

|

|

Control

method

|

Inverter

|

Inverter with PLC

|

Inverter

|

Inverter with PLC

|

|

Capacity

in tank

|

|

1.7L×4

containers

|

2.5L×4

containers

|

2.5L×4

containers

|

|

Rotation

rate

|

max. 240 rpm

|

max. 240 rpm

|

max. 210 rpm

|

max. 210 rpm

|

|

Automated

changing of rpm

|

-

|

3steps

|

-

|

3steps

|

|

Reverse

rotation

|

-

|

3steps

|

-

|

3steps

|

|

Imput Voltage

|

AC100V/200V

|

AC100V/200V

|

AC100V/200V

|

AC100V/200V

|

|

Driving

motor

|

750W

|

750W

|

750W

|

750W

|

|

Number of

programs

|

-

|

9

|

-

|

9

|

|

Weight of

machine

|

160Kg

|

160Kg

|

170Kg

|

170Kg

|

|

Dimension

(W×D×H)

|

640×680×1106

(Exclude Signal Tower)

|

|

|

Barrel

Finishing Machine 【Patented】

|

|

【Features】

This machine was developed

for finishing various kind of parts which

are high precision,easily chipped-out or complicated

shape.

- Easy to take container in

and out.

|

|

|

Cnotainer made

of urethan

|

|

|

|

|

|

Fitting with one

bolt

|

- Compact design. No need

a special tool for hoisting.

- Voltage:AC100V or AC200V

- Shorten processing time.

- Small footprint.

- No re-lining for a container

is required(made by urethan)

- Easy to install-deinstall

by one bolt fitting.

- 3 step-shift transmission

and reverse mode are available.You can set

programs up to 9 which could meet various

works.

|

|

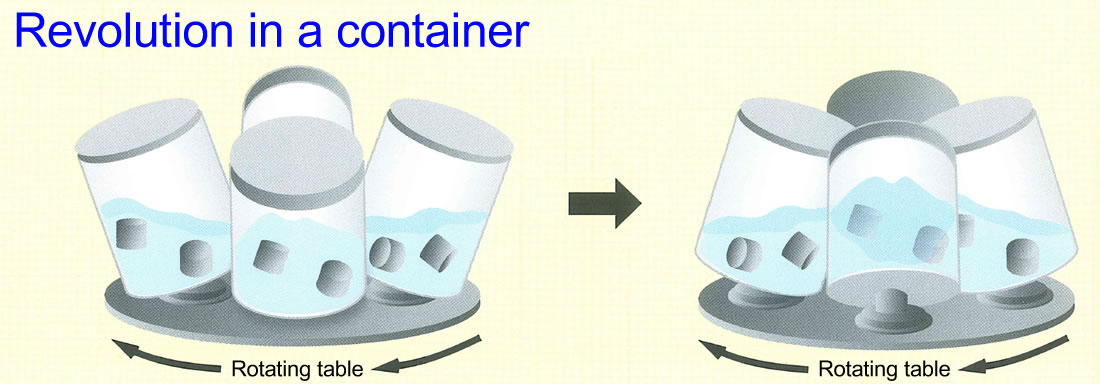

【3

dimensional relative movement】

The container are set and moved in a horizontal-leaning-revolution.

Within the container,works and polishing materials

are in a status as if kneaded toward the center

of container and the works are always staying

within the polishing materials. |

|

Advantages

of staying works within the polishing

materials.

|

1.Preventing

traces by hitting of works

| The polishing materials

are working as a shock-absorber

and preventing direct hitting of

works. |

2.Prevent

tangling, deforming or distortion

| Because, the works

are always staying within the polishing

materials. |

3.Significantly

reduce processing time

| Performance of polishing

is better than conventional ones. |

|

|

|

Conventional

|

Conventional

one has a horizontal rotation in which media,

works and water can be rotated horizontally.

The could give a separation between works and

media.

This would be a cause of hitting of works

and remaining traces and / or abrasion marks.

Such separation cannot give a well polishing

and should require a longer processing time. |

|

|

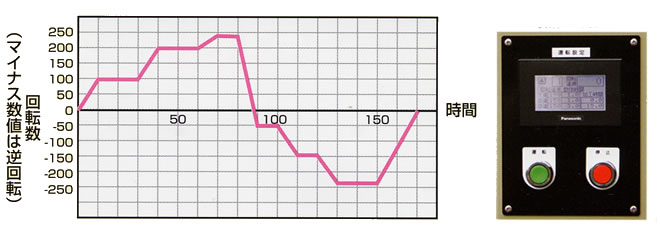

| 【Applicable

a fragile works】 |

To fragile

works such as ceramics or ferrite, sequencer control

can be applied which gives a stepwise changing of

rotational speed. For example, initially lower speed

and raising speed.

This prevented cracks.

|

|

|

Copyright (C) SANKEI High-Precision

Co.,Ltd. All Rights Reserved

2-3-4 Uriwariminami, Hirano-ku, Osaka City, Osaka 547-0023 Japan

TEL  +81-(0)6-4302-1871  FAX  +81-(0)6-4302-1885

Inquiry form |

|